Table of Contents

What Exactly Is Inventory Management (And Why Should You Care?)

Before we get into the nitty-gritty, let’s make sure we’re on the same page. What does “inventory management” actually mean for a small business owner like you?

Defining Inventory Management

Simply put, inventory management is the process of ordering, storing, using, and selling your company’s inventory. This includes managing raw materials, components, and finished products, as well as warehousing and processing such 1 items. For small businesses, especially those in retail or e-commerce, it essentially means knowing:

- What stock you have.

- Where it is located.

- How much you have of each item.

- When to order more.

It sounds straightforward, but mastering it involves tracking stock levels, predicting demand, handling storage, and minimizing costs.

The Real Costs of Poor Inventory Management

Why should you dedicate precious time to this? Not managing your inventory effectively can sink your business faster than you think. Consider these potential pitfalls:

- Lost Sales: Running out of popular items (stockouts) means missed revenue and frustrated customers who might go elsewhere – and never come back.

- Excess Storage Costs: Holding too much inventory (overstocking) ties up valuable cash and incurs costs for storage space, insurance, and potential damage or obsolescence. Think about products expiring, going out of style, or simply gathering dust.

- Spoilage and Obsolescence: If you sell perishable goods (like food) or items with short lifecycles (like tech or fashion), holding excess stock directly leads to waste and financial loss.

- Tied-Up Capital: Every dollar spent on inventory sitting on a shelf is a dollar you can’t invest in marketing, product development, or other growth areas. Poor inventory management significantly impacts your cash flow.

- Inefficiency: Searching for misplaced items or dealing with inaccurate counts wastes time and manpower, increasing operational costs.

Benefits of Getting it Right

On the flip side, effective inventory management brings significant advantages:

- Improved Cash Flow: By optimizing stock levels, you free up capital.

- Increased Sales & Customer Satisfaction: Having the right products available when customers want them boosts sales and loyalty.

- Reduced Costs: Minimizing storage fees, waste, and unnecessary purchases saves money.

- Better planning and forecasting: Understanding sales patterns helps you predict future demand more accurately.

- Operational Efficiency: Streamlined processes save time and reduce errors.

Ignoring inventory management means you’re operating without clear visibility – you might move forward, but you risk running into costly problems unexpectedly. Getting it right helps you see clearly, save money, keep customers happy, and ultimately, run a healthier, more profitable business. It’s not just about counting boxes; it’s a strategic function vital to your success.

Key Concepts You Need to Know

Before choosing methods or tools, let’s get familiar with some basic inventory language. Understanding these terms will make the whole process much clearer.

Types of Inventory

Your “inventory” might include more than just the finished products you sell. Depending on your business model, you might deal with:

- Raw Materials: The basic inputs used to create your products (e.g., fabric for clothing, ingredients for food).

- Work-in-Progress (WIP): Partially finished goods currently in the production process.

- Finished Goods: Products ready to be sold to customers. This is the most common type for retailers and many e-commerce businesses.

- Maintenance, Repair, and Operations (MRO) Goods: Items needed to run your business but not sold directly (e.g., cleaning supplies, packing materials, office supplies).

For many small businesses, especially retailers, the main focus will be on finished goods.

Essential Terminology

You’ll likely encounter these terms as you dive deeper:

- SKU (Stock Keeping Unit): A unique alphanumeric code assigned to each specific product and its variants (like size or color). Think of it as the product’s fingerprint for tracking purposes. Example: A blue, large t-shirt might have SKU TSHIRT-BLU-LG.

- Lead Time: The time it takes from placing an order with your supplier to receiving the goods. Knowing this is crucial for deciding when to reorder.

- Safety Stock (or Buffer Stock): Extra inventory held to mitigate the risk of stockouts caused by unexpected demand surges or supplier delays. It’s your “just in case” supply.

- Reorder Point (ROP): The specific inventory level that triggers a new order. It’s calculated based on lead time demand and safety stock. Formula often looks like: ROP=(AverageDailyUsage×LeadTime in Days)+Safety Stock.

- Carrying Costs (or Holding Costs): The total cost of holding unsold inventory. This includes storage space, insurance, handling, potential spoilage/obsolescence, and the cost of capital tied up. Often expressed as a percentage of inventory value.

- Stockout: Running out of a specific item. This leads to lost sales and customer dissatisfaction.

- Inventory Turnover Ratio: A measure of how many times inventory is sold or used during a specific period (usually a year). A higher ratio generally indicates efficient management (but too high might mean stockouts). Formula: Inventory Turnover = Average Inventory of Goods Sold.

Knowing these core concepts and terms is like having the right keys to unlock efficient inventory management. They help you quantify your stock, understand timing, calculate risks, and measure performance. Keep these definitions handy as you explore different techniques.

Popular Inventory Management Techniques

Okay, you understand the why and the what. Now let’s look at the how. Several methods exist to manage inventory flow and valuation. The best one for you depends on your business type, product nature, and goals.

First-In, First-Out (FIFO)

This is one of the most common methods.

- How it Works: Assumes the oldest inventory items (first in) are sold first (first out). Imagine a grocery store rotating milk cartons – newest ones go to the back.

- Pros:

- Reduces risk of spoilage or obsolescence, especially for perishable goods.

- Logical flow, easy to understand.

- Generally reflects the actual physical flow of goods.

- Valuation often aligns better with current market costs.

- Cons:

- Can be more complex to track physically if stock isn’t organized well.

- In times of rising prices, it can result in higher taxable income (as older, lower costs are matched with current revenue).

- Best For: Businesses selling perishable items (food, cosmetics), products with expiration dates, or items prone to becoming outdated (electronics, fashion).

Last-In, First-Out (LIFO)

LIFO is the opposite of FIFO.

- How it Works: Assumes the newest inventory items (last in) are sold first (first out). Think of a pile of sand – you take from the top layer added last.

- Pros:

- In inflationary periods, matching recent higher costs against revenue can reduce taxable income.

- Cons:

- Doesn’t typically match the actual physical flow of goods.

- Increases risk of spoilage or obsolescence as older stock may sit longer.

- Can be complex to manage.

- Important Note: LIFO is not permitted under International Financial Reporting Standards (IFRS) and has specific rules under US GAAP. Check with an accountant before considering LIFO for accounting purposes.

- Best For: Primarily businesses with non-perishable goods where price inflation is a significant factor and accounting implications are understood. Less common in practice for physical flow.

Just-In-Time (JIT)

JIT aims to minimize inventory holding altogether.

- How it Works: Inventory is ordered and received only as needed for production or customer sales. The goal is to have virtually zero inventory sitting idle.

- Pros:

- Dramatically reduces carrying costs (storage, capital).

- Minimizes waste from spoilage or obsolescence.

- Improves cash flow.

- Cons:

- Highly dependent on reliable suppliers and accurate forecasting. Any disruption (supplier delay, unexpected demand spike) can lead to immediate stockouts.

- Requires very efficient processes and communication.

- Less room for error.

- Best For: Businesses with predictable demand, strong supplier relationships, and efficient production or fulfillment processes. Often used in manufacturing but adaptable principles for retail.

ABC Analysis

This method categorizes inventory based on value or importance.

- How it Works: Divides inventory into three categories:

- A Items: High-value products making up a significant portion of total inventory value (e.g., 20% of items accounting for 80% of value). Require tight control, frequent review.

- B Items: Moderate value, moderate quantity. Require moderate attention.

- C Items: Low-value items, often high quantity (e.g., 50% of items accounting for 5% of value). Require simpler controls, less frequent review.

- Practical Steps:

- Calculate the annual consumption value for each item (Annual Demand x Item Cost).

- Rank items from highest value to lowest.

- Classify into A, B, and C categories based on cumulative value (e.g., A = top 70-80%, B = next 15-25%, C = bottom 5%).

- Benefits: Helps prioritize management efforts. Focus your time and resources on the ‘A’ items that have the biggest financial impact. Avoid spending too much time meticulously tracking low-value ‘C’ items.

Dropshipping

While not a traditional inventory holding method, it’s relevant for e-commerce.

- How it Works: You list products for sale but don’t keep them in stock. When a customer orders, you purchase the item from a third-party supplier, who ships it directly to the customer.

- Pros:

- No inventory holding costs or risks.

- Low startup cost.

- Wide product selection possible.

- Cons:

- Lower profit margins.

- Reliant on supplier for stock availability and shipping quality.

- Less control over customer experience.

- Managing returns can be complex.

Section Summary: Choosing Your Approach

No single technique is universally “best.” FIFO is great for perishables, ABC helps prioritize effort, JIT minimizes holding costs (if you can manage the risk), and dropshipping avoids holding stock altogether. You might even use a combination. Understand your products, sales cycle, and risk tolerance to pick the right strategy (or strategies) for your business.

Setting Up Your Inventory System: Step-by-Step

Ready to get organized? Here’s a practical roadmap to implement your inventory management system.

Step 1: Choose Your Method (Manual vs. Software)

How will you actually track everything?

- Manual Tracking (Spreadsheets):

- How: Using programs like Excel or Google Sheets to list items, SKUs, quantities, and track sales/purchases manually.

- Pros: Low cost (often free), simple for very small inventories, highly customizable.

- Cons: Extremely prone to human error, time-consuming, difficult to scale, lacks real-time updates, no advanced features like forecasting or low-stock alerts.

- Verdict: Okay for absolute beginners with fewer than 50 SKUs, but quickly becomes inadequate.

- Inventory Management Software:

- How: Dedicated software (cloud-based or installed) designed specifically for tracking inventory. Ranges from simple apps to complex systems integrated with accounting and POS.

- Pros: Automation reduces errors, real-time tracking, low-stock alerts, reporting and analytics, forecasting capabilities, integration with other business tools (e-commerce platforms, POS, accounting), scalability.

- Cons: Costs money (subscription or purchase), requires setup and learning curve.

- Verdict: The recommended route for most businesses serious about growth and efficiency. The investment pays off in accuracy and time savings.

Step 2: Organize Your Physical Stock

Whether in a storeroom, warehouse, or corner of your shop, physical organization is key.

- Clear Labeling: Assign and label every item with its unique SKU. Use barcode labels if you plan on using scanners. Make labels easy to read.

- Logical Layout: Arrange stock logically. Group similar items together. Place high-volume items in easily accessible locations. Consider using shelves, bins, and clear signage.

- Designated Areas: Have specific zones for receiving new stock, storing current inventory, and packing orders. This prevents mix-ups.

Think like a librarian – everything should have a specific place and be easy to find.

Step 3: Conduct an Initial Count (Physical Inventory)

You can’t manage what you don’t measure accurately. Start with a baseline.

- Why it’s crucial: Establishes the starting point for your tracking system. Reveals discrepancies between what you thought you had and reality.

- Tips for accuracy:

- Schedule it during non-business hours if possible to avoid disruption.

- Use teams of two (one counts, one records) for checks and balances.

- Be systematic – count section by section, shelf by shelf.

- Use count sheets or a mobile app connected to your software.

- Double-check counts, especially for high-value ‘A’ items.

This initial count might be painful, but it’s essential for accurate data moving forward.

Step 4: Implement Regular Tracking & Audits

Inventory levels constantly change. You need ongoing processes to keep data accurate.

- Record Everything: Diligently record all incoming stock (purchases, returns) and outgoing stock (sales, usage, damages). Use your chosen system (spreadsheet or software).

- Regular Audits: Don’t rely solely on your system data. Perform regular physical checks to ensure reality matches records. Two common methods:

- Cycle Counting: Counting small subsets of inventory regularly (e.g., daily or weekly) on a rotating basis. Less disruptive than a full count, catches errors faster, focuses effort (e.g., count ‘A’ items more often).

- Annual Physical Inventory: A full count of all inventory, usually done once a year. More disruptive but provides a complete picture. Often required for financial reporting.

- Importance of Reconciliation: When audits reveal discrepancies (and they often will!), investigate the cause (theft, damage, data entry error, etc.) and adjust your records. This helps identify and fix process weaknesses.

Step 5: Integrate with Other Systems (POS, E-commerce)

For maximum efficiency, especially if you sell through multiple channels, integration is key.

- Point of Sale (POS): If you have a physical store, integrating your POS system with inventory software automatically deducts items as they’re sold.

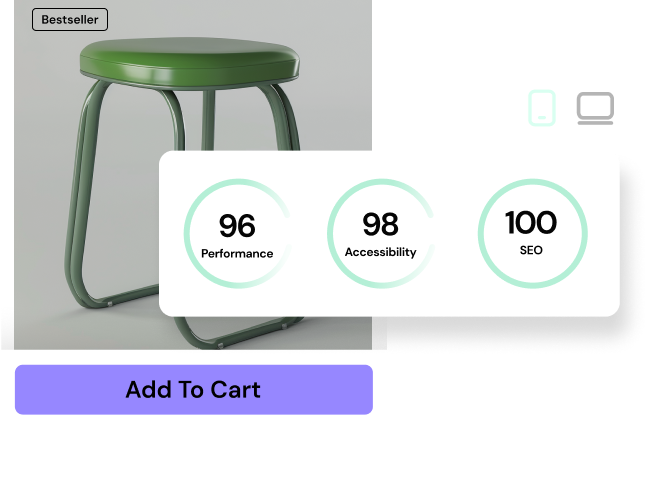

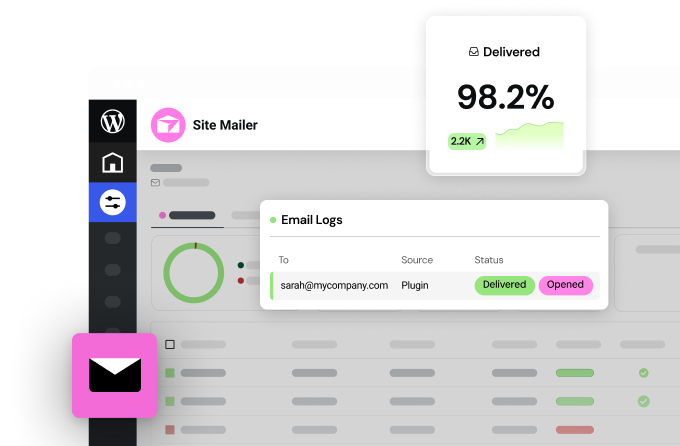

- E-commerce Platform: Connecting your online store (perhaps one built with a flexible platform like WordPress using Elementor for design) ensures that online sales update inventory levels automatically, preventing overselling.

- Accounting Software: Integration streamlines financial reporting by automatically updating cost of goods sold and inventory asset values.

This creates a unified view of your inventory across all sales channels.

Setting up involves choosing your tracking tool, organizing your physical space, getting an accurate starting count, establishing regular tracking and auditing routines, and ideally, integrating your system with other business tools. It requires discipline but forms the backbone of effective inventory control.

Leveraging Technology: Tools & Software

While manual methods exist, technology significantly boosts accuracy and efficiency. Let’s look at the options.

Spreadsheets (The Starting Point)

As mentioned, tools like Microsoft Excel or Google Sheets can work for very basic needs. You can create templates to track SKUs, quantities, reorder points, and suppliers.

- Pros: Familiar, free/low cost.

- Cons: Error-prone, manual updates, no real-time visibility, limited reporting, not scalable.

Think of spreadsheets as training wheels – helpful initially, but you’ll likely outgrow them.

Dedicated Inventory Management Software

This is where the real power lies. Features vary, but look for:

- Real-time Tracking: Updates inventory levels instantly across channels as sales or purchases occur.

- Reporting & Analytics: Provides insights into sales trends, turnover rates, low stock, aging inventory, and profitability per item.

- Forecasting: Uses historical data to help predict future demand, improving ordering accuracy.

- Low-Stock Alerts: Automatically notifies you when inventory reaches the reorder point.

- Barcode Scanning: Speeds up receiving, counting, and order picking; reduces errors.

- Multi-location Management: Tracks inventory across multiple warehouses or stores.

- Integrations: Connects seamlessly with e-commerce platforms (like WooCommerce, Shopify – often used with WordPress/Elementor sites), POS systems, accounting software (QuickBooks, Xero), and shipping carriers.

- User Management: Allows different team members access with specific permissions.

Examples: Zoho Inventory, Katana, Cin7, NetSuite (more enterprise-level). Many options exist at different price points.

Barcode Scanners & POS Systems

- Barcode Scanners: Used with inventory software, these dramatically speed up data entry and reduce errors compared to manual typing. Can be simple USB scanners or mobile apps on smartphones.

- POS Systems: Modern POS systems (like Square, Clover, or integrated e-commerce POS) often include basic inventory tracking. Integrating a robust POS with dedicated inventory software provides the best results.

E-commerce Platform Integrations

If you sell online, this is crucial. Your inventory system should talk directly to your website.

- Why it Matters: Prevents selling items you don’t have. Provides accurate stock levels to customers online. Centralizes order management.

- Look For: Software that explicitly integrates with your e-commerce platform (e.g., WooCommerce if you’re using WordPress). This seamless connection is vital for businesses leveraging powerful website builders like Elementor to create their online stores.

Choosing the Right Tool for Your Business

Don’t just pick the fanciest software. Consider:

- Your Business Size & Complexity: How many SKUs? Multiple locations? Manufacturing involved?

- Budget: Costs range from free trials or around $20 per month to hundreds or thousands.

- Features Needed: Do you need advanced forecasting, batch tracking, or multi-location support right now?

- Integrations Required: Does it connect with your existing POS, e-commerce platform, and accounting software?

- Ease of Use: Can you and your team learn and use it effectively? Look for good support and documentation.

- Scalability: Will the tool grow with your business?

Start with your essential needs and choose a tool that meets them well, with room to grow.

Technology transforms inventory management from a manual chore into a strategic advantage. While spreadsheets are a basic start, dedicated software integrated with barcode scanners, POS systems, and your e-commerce platform offers the accuracy, real-time data, and efficiency needed for growth. Choose tools wisely based on your specific business requirements.

Common Challenges and How to Overcome Them

Even with the best intentions and tools, you might encounter bumps in the road. Here are common challenges and how to tackle them:

Challenge: Inaccurate Data

- Problem: Your system says you have 10 units, but the shelf is empty (or has 15). This leads to stockouts or overstocking.

- Causes: Human error in data entry, theft, damage, items misplaced, receiving errors, unrecorded transactions.

- Solution:

- Implement regular cycle counting: Catch errors sooner.

- Use barcode scanners: Minimize manual entry mistakes.

- Train staff thoroughly: Ensure everyone follows procedures for recording stock movements.

- Secure your stock: Reduce opportunities for theft or unauthorized use.

- Reconcile discrepancies promptly: Investigate why counts are off and correct the root cause.

Challenge: Lack of Process

- Problem: No clear, documented procedures for receiving, storing, counting, or shipping inventory. Everyone does things differently.

- Causes: No formal system established, lack of training, inconsistent execution.

- Solution:

- Document your procedures: Create simple, clear instructions for each inventory task.

- Train your team: Ensure everyone understands and follows the documented processes.

- Assign responsibility: Make specific individuals accountable for different inventory tasks.

- Use checklists: Help ensure steps aren’t missed.

Challenge: Poor Forecasting

- Problem: Consistently ordering too much or too little stock due to inaccurate demand prediction.

- Causes: Not analyzing historical sales data, ignoring seasonality or trends, unexpected market shifts, lack of forecasting tools.

- Solution:

- Use inventory management software with forecasting features: Leverage historical data.

- Analyze sales reports regularly: Identify trends, seasonality, and fast/slow-moving items.

- Factor in lead times and safety stock: Buffer against uncertainty.

- Collaborate with sales/marketing: Get insights on upcoming promotions or expected demand changes.

- Start simple: Even basic tracking of past sales beats pure guesswork.

Challenge: Scaling Issues

- Problem: The simple system that worked when you started is now overwhelmed by growth (more products, higher volume, multiple locations).

- Causes: Using inadequate tools (like spreadsheets), manual processes can’t keep up, lack of warehouse organization.

- Solution:

- Invest in scalable software: Choose a system that can handle growth.

- Automate processes: Use barcode scanning, integrations.

- Optimize warehouse layout: Improve efficiency as volume increases.

- Continuously review and adapt your processes: What worked last year might not work next year.

Challenge: Handling Returns Effectively

- Problem: Returned items aren’t processed correctly, leading to inaccurate stock counts and potential resale of damaged goods.

- Causes: No clear returns process, inadequate inspection, delays in putting sellable items back into inventory.

- Solution:

- Establish a clear Returns Management Authorization (RMA) process: Document steps for receiving, inspecting, and dispositioning returns (resell, refurbish, discard).

- Inspect returns promptly and thoroughly: Determine if the item can be resold.

- Update inventory records immediately: Add sellable items back to stock in your system.

- Track reasons for returns: Identify potential product quality issues or description inaccuracies.

Inventory management isn’t always smooth sailing. Expect challenges like inaccurate data, inconsistent processes, forecasting errors, scaling difficulties, and messy returns. The key is to anticipate these issues, implement robust processes and tools, train your team, and continuously monitor and adjust your system.

Putting It All Together: Best Practices Checklist

Feeling overwhelmed? Let’s boil it down to a handy checklist of best practices:

- Assign Unique SKUs: Assign a unique identifier to each product variant.

- Organize Physically: Implement a logical layout with clear labeling in your storage area.

- Perform an initial full count to establish an accurate baseline.

- Choose the Right Tracking Method: Start with spreadsheets if necessary, but plan to upgrade to dedicated software.

- Implement Regular Audits: Use cycle counting and/or annual physical counts.

- Record All Stock Movements: Diligently track purchases, sales, returns, and damages.

- Reconcile Discrepancies: Investigate and correct differences between physical counts and system data.

- Use Technology Wisely: Leverage software, barcode scanners, and integrations (POS, e-commerce).

- Analyze Your Data: Use reports to understand sales trends, turnover, and profitability.

- Implement Forecasting: Use data (and software) to predict future demand.

- Set Reorder Points & Safety Stock: Automate reordering and buffer against stockouts.

- Apply ABC Analysis: Prioritize management efforts on high-value items.

- Choose Appropriate Valuation Methods (FIFO/LIFO – consult accountant): Understand how inventory flow affects costs and taxes.

- Document Processes: Create clear procedures for all inventory tasks.

- Train Your Team: Ensure everyone understands their role and follows procedures.

- Secure Your Inventory: Implement measures to prevent theft and damage.

- Manage Returns Efficiently: Have a clear process for handling returned goods.

- Review and Adapt: Continuously monitor performance and adjust your system as your business evolves.

Conclusion: Take Control of Your Stock

Inventory management might not be the most glamorous part of running your small business, but it’s undeniably one of the most critical. From improving cash flow and customer satisfaction to reducing waste and increasing efficiency, getting a handle on your stock pays dividends.

Start small if you need to. Begin by organizing your space, assigning SKUs, and choosing a simple tracking method. As you grow, embrace technology like dedicated software and integrations – especially with your online storefront, which might be beautifully crafted using tools like Elementor on WordPress. The key is to be systematic, diligent, and data-driven.

By implementing the concepts and steps outlined here, you’re not just counting items; you’re building a more resilient, efficient, and profitable business. So, take a deep breath, roll up your sleeves, and start taking control of your inventory today. You’ve got this!

Looking for fresh content?

By entering your email, you agree to receive Elementor emails, including marketing emails,

and agree to our Terms & Conditions and Privacy Policy.